Starting a Keycap Business

Three months ago, after many good years of service, my SteelSeries Apex keyboard started to give out. Presses would intermittently register multiple times or not at all. It wasn’t all that surprising–it had lasted longer than any keyboard I’d owned and I’d worn many of the letters off the keycaps years ago. I knew it was time to finally take a plunge I’d been considering for a while: I needed to buy a mechanical keyboard.

Some say mechanical keyboards are a rabbit hole: You buy one, then end up with five. I’d say that’s mostly accurate, but in my case a massive understatement.

Shortly after buying a new Akko X Ducky keyboard, I decided I’d like to try other switches, which led to purchasing sampler packs, which led to realizing if I wanted to use my favorite ones (ZealPC Zilent 65g are to die for), I’d need to build my own keyboard. That led to buying a Levinson kit off keeb.io and then to searching for cool custom keycaps to put on it.

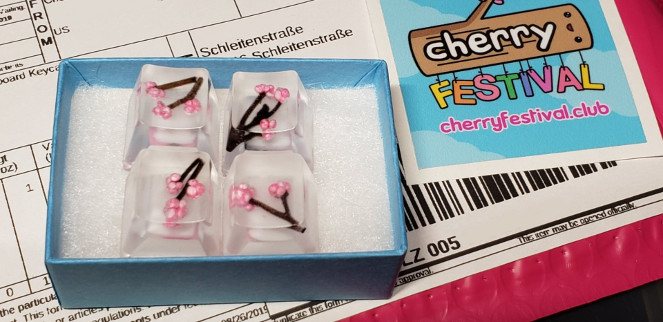

My fascination with the keycaps was immediate. I had never considered being able to choose the look at such a granular level or have artwork embedded within the keys. The opportunities for personalization were endless. Perhaps even more interesting than the end result, though, was the process of making them. I quickly decided that instead of buying custom keycaps for my Levinson, I’d build them just like I was building the rest of it.

Creating keycaps is far and away more complicated than soldering together a custom keyboard. I knew this when I started, but these past few months the reality of what I decided to do really set in. I converted half my basement into a shop with vacuum and pressure chambers, air and heat dryers, an SLA printer, ultrasonic cleaners, and polishing tools. Syringes and popsicle sticks litter the repurposed desks, and nearly a thousand dollars worth of chemicals fills the multiple new shelving units I had to buy to hold them all. A fume hood hangs over a wall of respirators, gas and vapor filters, and UV goggles. Where there was once a window, there is now an exhaust.

Something to understand about making custom keycaps is it’s not a significant stretch from making one to making a thousand. The equipment needed to even make the first one properly is so extensive (and expensive) it quickly dawns on you that stopping there is insane. You need a miniature factory to make high quality keycaps, and if you’ve got a miniature factory, you might as well run it.

When I started this, I didn’t intend to make money off it. By the time I had my process refined, though, I’d started reading up on the legal and financial requirements. I learned about different business structures, how to file quarterly taxes, what state and local permits I’d need, and how to track all the expenses. The sheer amount of auxiliary learning needed was unexpected, but fascinating. What size are shipping labels? Is a thermal printer warranted? How do you manage customs forms for different countries? What sort of agreement do you need with a parcel carrier to use prepaid return labels? Which materials do you pay tax on when buying versus collect tax on when selling? Do you need insurance? Which new accounts do you need to open at the bank?

Beyond that are the logistics issues of running a workbench as a professional shop with an internet presence. How do you line up new products on a photo back plane to get the same shot every time? How do you configure product lighting? How do the APIs work to pull listings onto your website? How do you store and track stock in real-time and ship it quickly?

And never mind the thousands of questions regarding the actual process of making the keycaps themselves, which is still largely uncharted territory even in the casting community. With a few notable exceptions like a pressure pot, the equipment, timings, processes, and art methods are as different as the keycap makers themselves. StackOverflow won’t save you here, but in a way that’s exciting.

I’m happy to say that falling down the rabbit hole has worked out so far. My new shop, Cherry Festival, has completed over 100 orders in its first two months of operation and I now have a place on people’s keyboards in most US states, Canada, the UK, Norway, Sweden, Germany, Australia, and even Japan.

Some day I may even get around to building that Levinson keyboard that started all of this.